UKUAT member Zayndu recently produced a video explaining its groundbreaking ActivatedAirTM seed priming technology, which we wanted to share to help growers understand its benefits.

In a nutshell, Zayndu’s technology boosts crop yield, seed health, and germination, as well as synchronisation – simply by treating seeds with cold plasma. With the use of cold plasma, our technology successfully harnesses the power of lightning to act as a natural fertilizer and disinfectant for crops, allowing them to reach their full potential.

Watch the full video here.

Zayndu CEO Ralph Weir introduces ActivatedAirTM by saying it helps produce bigger, stronger and healthier plants without artificial chemicals by encouraging the seed to utilise its resources better.

Zayndu’s new video is shot on location at its UK headquarters at the Advanced Technology Innovation Centre in Loughborough, and features members of the Zayndu team discussing every aspect of ActivatedAirTM.

At the heart of the Z-Series plasma seed treatment machine is a plasma generator using high-voltage electricity to expose seeds to an environment similar to a lightning strike, said James Seaman, director of engineering at Zayndu.

One of the key features of the machine is its simple user interface.

“We don’t want our customers spending lots of time upskilling and training their operators. We want the machines to be used out of the box with minimal skill required,” said James.

The plasma treatment removes the external waxes on the seed surface, increasing the water permeability of the seeds and enabling them to absorb water more efficiently, explained Dr Alberto Campanaro, head of plant science at Zayndu.

This produces faster germination, which, so far, Zayndu’s plant science team has tested around 130 varieties spanning 50 plant species.

“Generally speaking, what we see in terms of yield increase from using the ActivatedAirTM technology is somewhere in the region of 20%, up to 30%,” Alberto added.

What does this mean for a grower in practical terms?

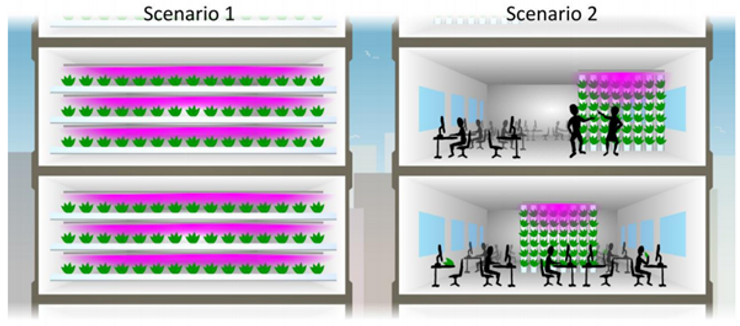

“Vertical farmers find ActivatedAirTM particularly attractive because of the decreased (crop) cycle time,” said Nathanael Dannenberg, sales manager at Zayndu. “It means their crop under lights for less time, which makes their operational costs lower per cycle.”

Similarly, greenhouse growers can increase output by running more crop cycles per year, maximising their growing space, continued Nathanael.

In conclusion, Ralph added that ActivatedAirTM enables growers to lower their cost of production, increase their output, and deliver better crops without using artificial chemicals.

“It’s a very exciting proposition for a grower.”

Watch the ActivatedAirTM video for more information or contact the Zayndu team via LinkedIn or the Zayndu website to learn more.

by Will Charlton, for and on behalf of Zayndu.